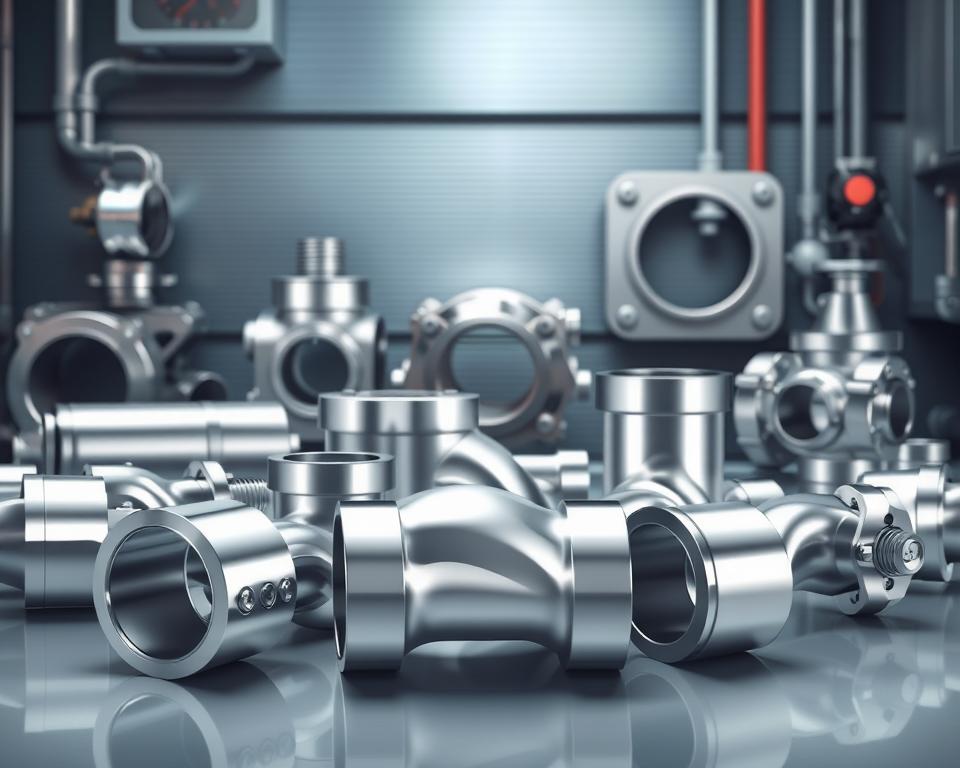

Superior Tri-Clamp Clean-Flow Fittings for Sterile Environments

Across sectors in which contamination can be fatal, even tiny voids are significant. For this reason, companies like Installation Parts Supply specialize in precision-engineered solutions minimizing contamination. These hygienic connection systems merge durability with smooth installation, rendering them a top choice for sites that insist on flawless results.

These fittings aren’t just about eliminating leakage – they’re engineered to satisfy the rigorous criteria of food manufacture, drink manufacturing, and biopharma plants. Made from oxidation-proof steel, they survive repeated washdowns while maintaining structural integrity. The design philosophy parallels industry leaders like Alfa Laval, focusing on Tri clamp fittings smooth surfaces and speedy removal.

Why are these fittings different? Think single-handed setup and wrench-free servicing. Workers appreciate the intuitive design during fast-paced operations, while supervisors cherish repeatability across pipelines. Every piece undergoes strict quality checks to guarantee adherence to FDA and 3-A Sanitary Standards.

Critical Findings

- Chosen by specialists for fluid-tight security in high-stakes contexts

- Fabricated in industrial-grade stainless steel for robust longevity

- Eases fulfillment of food safety and pharmaceutical standards

- Reduces downtime through quick-release setup and scrub-down

- Underwritten by testing programs on par with global benchmarks

Solution Summary and Core Advantages

Dependable joints are the backbone of contamination-free operations. Installation Parts Supply engineers components that merge exact machining with hands-on utility. Their solutions grant tight containment while easing cleaning cycles—critical for industries where efficiency meets cleanliness.

Elite Grade & Hygiene Compliance

Every unit undergoes rigorous testing to reach international criteria. The metals oppose oxidization, even after continual wash-downs. Hermetic joints block pathogen buildup, a feature applauded by dairy processors and pharmaceutical manufacturers alike.

These components match the standards of leaders like Alfa Laval, guaranteeing smooth surfaces and uniform dimensions. Configurable designs adapt to existing setups, cutting upgrade expenses. Workers record 30% speedier setups compared to traditional threaded systems.

Supplier-Specific Advantages

Bespoke machining distinguishes this company. Need a unique angle or specialized finish? Their team co-designs with users to create exact matches. Immediate dispatch and 24/7 technical support sustain throughput.

The pluses go past toughness. No-tool breakdown slims idle time during sanitation audits. Brew houses using these connectors report fewer production stoppages and steady throughput. It’s not just about meeting regulations—it’s about leapfrogging requirements.

Engineering Specs & Construction Details

Exact machining marries multi-purpose use in advanced facility setups. Installation Parts Supply crafts components that harmonize stringent tolerances with variable options. Their strategy delivers trouble-free merging into current lines while keeping exacting sanitary guidelines.

Tailored Alloys and Textures

Every project has unique needs. That’s why materials range from 304 to 316L stainless steel, chosen due to strength and corrosion resistance. Surface treatments like electro-finishing generate mirror-like smoothness, lowering germ cling by up to 40% compared to standard finishes.

| Finish Type | Key Feature | Compliance |

|---|---|---|

| Electropolished | Ultra-smooth surface | ASME 3A, ISO 9001 |

| Mechanically Polished | Cost-effective shine | 3-A Sanitary Standards |

| Bead-Blasted | Non-reflective texture | FDA Food Code |

Manufacturing processes employ beam-based sensors to confirm uniform wall thickness. Tight tolerances (±0.005″) avoid frail sections in high-pressure environments. During quality checks, components receive X-ray scans and pressure tests to find microscopic flaws.

Tailoring surpasses looks. Clients order specific angles, flange sizes, or unique coatings for chemical resistance. These bespoke solutions help industries adhere to shifting standards without tearing out full lines.

Implementation and Use-Cases for Tri-Clamp Sanitary Links

Today’s accelerated sites expect hardware that fit fast yet work steadily. These joining solutions excel in environments where speed meets strict hygiene. Their design eliminates complex tools, allowing teams to retain focus on throughput rather than installation woes.

Simplified Assembly Process

Dual flange faces and a centered gasket generate error-proof locks in seconds. Crew place the parts, insert the closure device, and seal by hand – no wrenches required. This approach minimizes assembly faults while keeping even compression across the joint.

| Step | Traditional Method | Modern Solution |

|---|---|---|

| Alignment | Thread matching required | Flanged ends self-center |

| Sealing | Multiple tape layers | Single food-grade gasket |

| Securing | Torque wrench needed | Hand-tightened mechanism |

Universal Links Among Units

Between polished pipes and reactors, these interfaces join varied parts with ease. The uniform design aligns with various diameters, allowing quick reconfigurations during product changeovers. Dairy plants regularly utilize them to alternate between cleaning cycles and production runs with zero hassle.

Maintenance teams enjoy how components disassemble for thorough sanitation. Smooth surfaces stop gunk accrual, while the absence of threads avoids bacterial hideouts. Weekly cleanings run in half the duration compared to older connection methods.

Sector Uses & Regulatory Alignment

Across nano-brew houses to biotech sites, modern facilities lean on connectors that meet multiple objectives while conforming to tight guidelines. Installation Parts Supply provides solutions trusted across vital fields where product purity remains paramount. Their designs tie output to standards, forging setups that work under strain.

Edibles, Drinks, and Drug Industries

Throughout refreshment operations, speedy-switch links simplify switching between recipes or cleaning cycles. Breweries utilize tri-clover tees to manage complex flow paths while eliminating cross-mix hazards. Pharmaceutical manufacturers trust leak-free closures to guard delicate ingredients during sterile transfers.

These parts are available in varied dimensions to match piping layouts, from small-scale laboratories to large-scale fermentation tanks. Dairy processors like how standardized parts shorten holds during equipment upgrades. Even tiny alterations in production processes are embraced through modular designs.

Alignment to Global Codes

Every unit hits or surpasses benchmarks set by global organizations. ASME-certified materials endure thermal stress in pasteurization systems, while ISO-compliant finishes block germ adhesion. The 3-A symbol assures fitness for direct contact with consumables.

Tri-Clamp connectors showcase the promise. Their uniform dimensions supply hermetic closure across automated lines. Third-party audits check sourcing from raw materials to finished goods, supplying auditors comfort.

By tracking these benchmarks, facilities speed inspection clearance and clear checks smoothly. It’s not just about sidestepping fees—it’s about gaining market credibility through transparent sanitation.

Last Words and Forward Path

Deciding on solutions that unite throughput and regulation defines production wins. Installation Parts Supply supplies systems blending strength and sanitation, ensuring leak-free performance across food, pharma, and beverage environments. Their products satisfy rigorous standards while simplifying daily workflows through easy install.

With choices across alloy types and polishings, solutions tailor to distinct facility goals. Whether moving scalding media or constant washdowns, material choices and surface treatments extend lifespan. Professionals praise the wide selection of connection types tailored to set velocity and line pressure.

Procurement stays smooth, with professional assistance provided to pair process demands. Express delivery and minimized wait times reduce production stalls during upgrades or replacements. Scheduled upkeep becomes effortless thanks to no-tool breakdown and smooth surfaces that resist residue buildup.

Looking to improve operational trust? Reach out to Installation Parts Supply to investigate bespoke options – from tri-clover to tri-clamp variants – backed by industry-leading quality assurance. Their team makes sure you satisfy today’s rules while positioning you for upcoming needs.